High mechanical, high dielectric performance PTFE/TPU laminate tape -Flexible flat cable bus application in extreme dynamic working conditions

In the fields of industrial robots, medical interventional instruments, semiconductor manufacturing test equipment and aerospace special instruments, the cable wires can reach the very fine degree of AWG 56 (conductor diameter 0.0124 mm), the operating temperature requirements range from -40 degrees to 75 degrees, and it needs to withstand 4 million minimum radius bending fatigue without compromise. These extreme conditions place extremely demanding requirements on the dielectric and mechanical properties of the insulation and shielding materials of the cables.

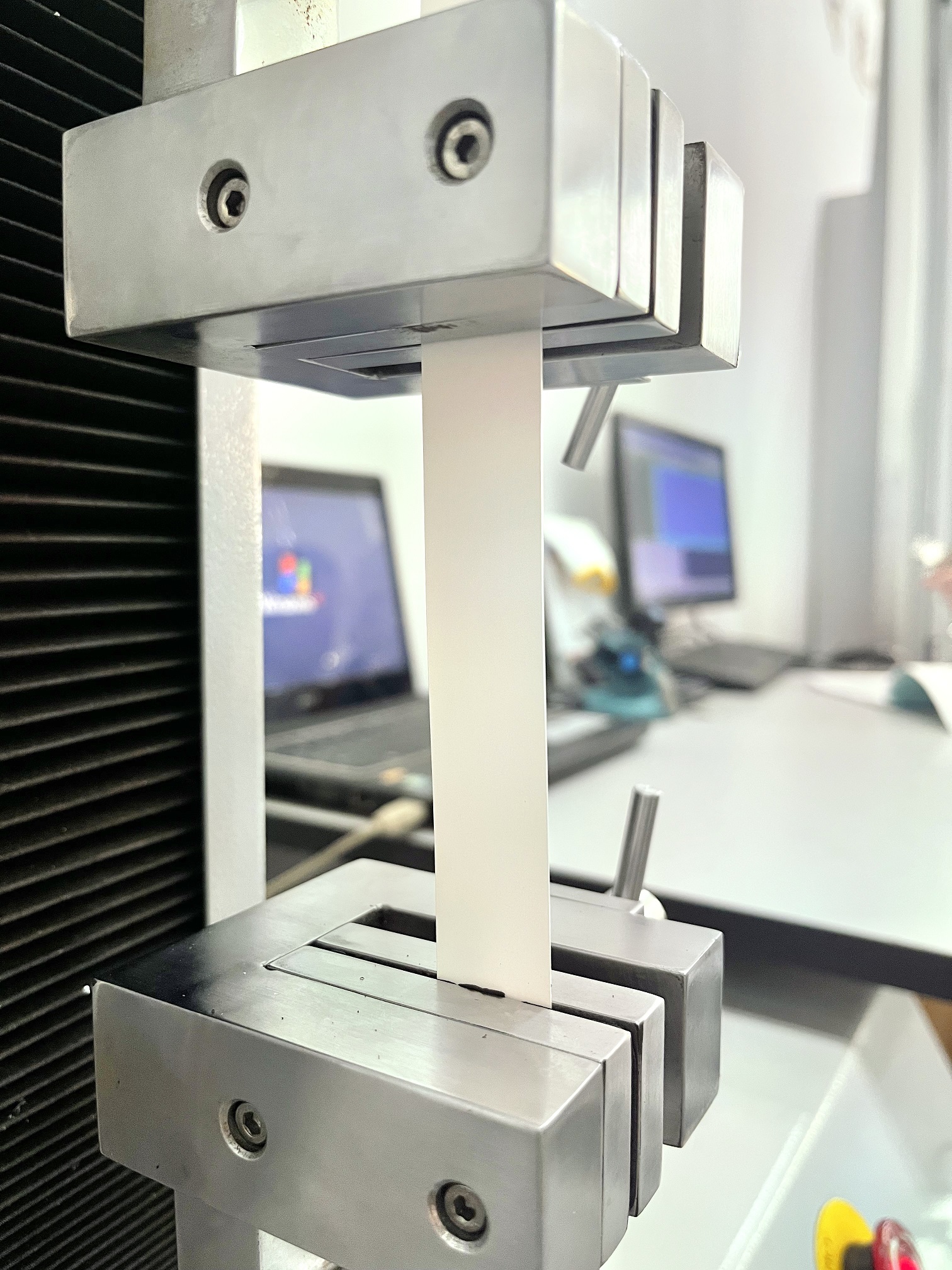

Facing this application challenge, based on many years of composite and laminate tape process and film knowhow, KEMAITE bravely combined the physical modification of PTFE high dielectric performance functional film through surface optimization with large-thickness (75 micron) high mechanical performance PU unconventional elastic film, and laminated them by high-temperature electromagnetic thermal bonding process to reach the excellent mechanical and dielectric properties (elongation greater than 30%, 4 million bending - bending radius 2cm, dielectric constant <2.1. Dielectric loss tangent < 2×10-4. Dielectric strength (KV/mm) >17) suitable for weather-resistant and damage-resistant coated films for highly flexible cables.

This creative product is lightweight, easy to apply to hot compresses, resistant to large dynamic high-frequency motion loads, and self-lubricating and wear-resistant. It has passed the verifying application test in the German client and entered their serials production, which is the first special cable application in the relevant industry branch and fills the gap in this special industrial area.

Super Flexible extrem dynamic data row flat cable (bottom left: industrial robot applications; Bottom right: Ultra-fine control cable for medical interventional devices)

Kemaite

THE END